点击蓝字

关

注

我

们

导语:

在轨道交通领域,噪音治理与部件耐久性一直是行业痛点。Delkor Rail面对英国百年铁路线的严苛需求,如何通过Endurica CL仿真技术,将40余次物理测试压缩至1次,同时通过EN13481 Cat C认证?本文揭秘其从技术突破到商业落地的全过程,看仿真如何成为高端制造的“隐形引擎”。

ENDURICA 用户聚焦

ENDURICA USER SPOTLIGHT

Delkor Rail is a worldwide supplier of high-quality, resilient bonded rail baseplates, platform gap filler, and rolling stock products, with over 30 years of experience providing technical advice and quality components to the world’s rail construction industry. | Delkor Rail 是全球高品质弹性体轨道基板、站台间隙填充装置及机车车辆产品的供应商,拥有超过30年的经验,为全球铁路建设行业提供技术咨询与优质部件。 |

Based in Sydney Australia, Delkor Rail has worked on projects in Australia and all over the world, including the London Underground, and projects in Canada, USA, Madrid, Barcelona, Singapore, Hong Kong, Malaysia, Taiwan, Germany, Switzerland, and New Zealand. | Delkor Rail总部位于澳大利亚悉尼,参与过澳大利亚及全球多个项目,包括伦敦地铁,以及加拿大、美国、马德里、巴塞罗那、新加坡、中国香港、马来西亚、中国台湾(地区)、德国、瑞士和新西兰的项目。 |

Elastomeric Products Include: | 弹性体产品包括: |

Track Products: ① Multiple rail fastening systems including those focused on high vibration and noise attenuation | 轨道产品: ① 多种轨道紧固系统(含高振动与降噪型) |

| |

Rolling Stock: ① Suspension components | 机车车辆产品: ① 悬挂部件 |

| |

Platform Gap Filler: A sturdy, hard-wearing rubber strip mounted along the edge of a train platform to reduce the gap between the platform and the entrance of a passenger train | 站台间隙填充装置: 安装在站台边缘的坚固耐磨橡胶条,用于缩小站台与列车入口的间隙 |

The software has been working well for us. The combination of Ansys, the material data we have obtained and the ability to perform fatigue simulations has allowed us to design products that would not have been possible previously (without extensive physical testing) — Robert Barnbrook Product Engineer Delkor Rail Pty Ltd. | 该软件表现优异。通过Ansys、材料数据与疲劳仿真能力的结合,我们设计出了以往(未经大量物理测试)无法实现的产品。 —— Robert Barnbrook,Delkor Rail Pty Ltd. 产品工程师 |

客户耐久性要求

CLIENT DURABILITY REQUIREMENT

The Northern City Line of the Great Northern Network Rail system in the United Kingdom started operation in 1904. Since 2015 the line has run a minimum of six trains per hour and extended operating hours until midnight. | 英国大北方铁路网络北城线于1904年投入运营。自2015年起,该线路每小时至少运行六班列车,运营时间延长至午夜。 |

| |

Noise complaints from residents near the Moorgate Branch rose to the attention of London’s Mayor and political pressures resulted in a budget being formed to deal with noise complaints — and Network Rail dedicating a team for a quick solution. | Moorgate支线附近居民的噪音投诉引起伦敦市长关注,政治压力促使预算拨款以应对噪音问题,Network Rail组建团队寻求快速解决方案。 |

| |

Delkor Rail’s challenges included maximizing N&V reduction, maintaining TOR, using the existing hole centers, retaining BH rail and key protocols, and completing all work through EN13481 Cat C testing. All while assuring sufficient durability. | Delkor Rail面临的挑战包括:最大化降噪减振、保持轨道几何参数(TOR)、利用现有孔位中心、保留BH钢轨与关键协议,并通过EN13481 Cat C测试完成所有工作,同时确保足够的耐久性。 |

解决方案

SOLUTION APPROACH

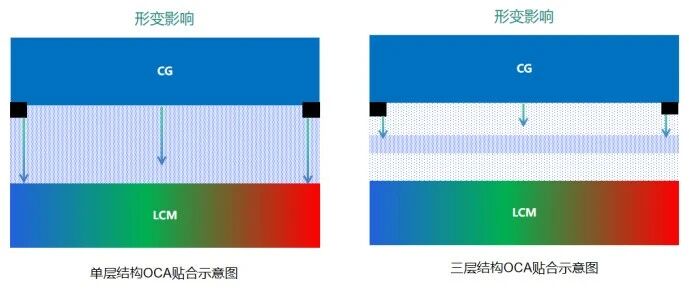

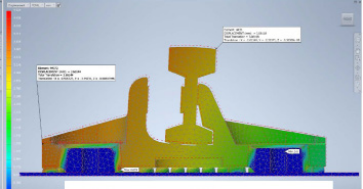

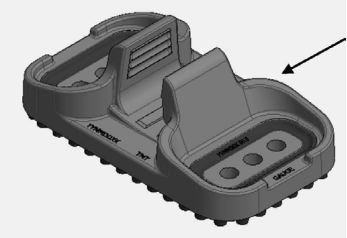

The Delkor Egg baseplate helps to reduce structure-borne vibration and noise. It is comprised of a top plate and base frame that are vulcanized (bonded) together by means of a natural rubber element which helps achieve a very low static stiffness while still ensuring a high degree of rail stability. | Delkor Egg基板可降低结构振动与噪音。其由顶板与底座框架通过天然橡胶元件硫化(粘合)而成,既能实现极低静态刚度,又能确保轨道高度稳定性。 |

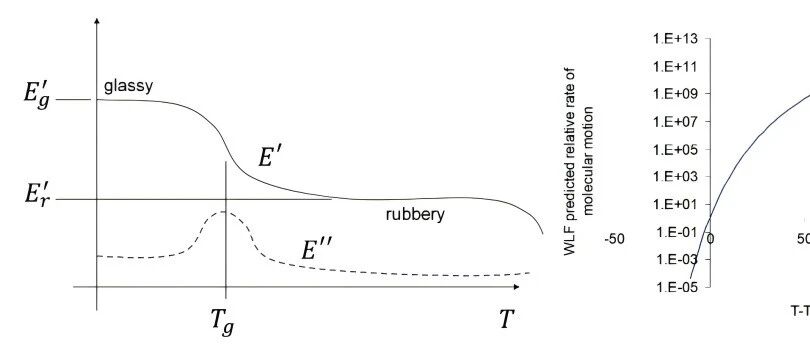

Endurica’s tools help Delkor to fulfill regulatory requirements on part durability and allows rubber stiffness to be optimized for the type of stock and speed. | Endurica工具帮助Delkor满足部件耐久性的法规要求,并针对车辆类型与速度优化橡胶刚度。 |

Delkor’s client, UK-based Network Rail Acceptance Panel (NRAP), gave full acceptance of the solution. | Delkor的客户英国Network Rail验收委员会(NRAP),已全面认可该解决方案。 |

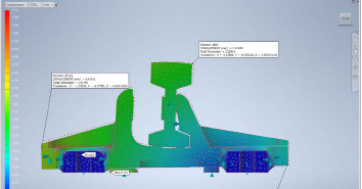

Delkor uses Endurica CLTM with ANSYS to model Egg | Delkor运用Endurica CL™联合ANSYS对Egg基板进行耐久性建模。 |

重新设计的铸造工艺图示 Redesigned casting image | |

Endurica Value Add for Delkor Rail: ① Save costs of multiple physical tests for design iterations | Endurica为Delkor Rail带来的价值: ① 节省多次设计迭代的物理测试成本 |

Before Endurica, we went through 40+ design iterations trying to reduce the strain amplitude as much as possible. We also went through 4 or 5 rounds of physical testing before a successful test. Since we adopted Endurica CL, we have been able to compare the fatigue life for new designs against previous designs that we have been successful with. This has meant that we can produce a suitable design with only a handful of design iterations and a single physical test. | 使用Endurica前,我们进行了40多次设计迭代以尽可能降低应变幅值,还需经过4-5轮物理测试才能成功。 自采用Endurica CL后,我们可将新设计的疲劳寿命与既往成功设计对比,仅需少量迭代与一次物理测试即可完成设计。 |

END

想了解Endurica如何为您的项目实现‘仿真替代物理测试’,节省50%以上研发成本?

扫码联系技术顾问!

联系方式 | 易瑞博科技(天津)有限公司 |

电话:022-28750273 | |

邮箱:business@e-rubber.com.cn | |

可提供服务:橡胶材料非线性力学性能测试、橡胶疲劳耐久性测试、橡胶构件疲劳耐久性分析 |

—关注我们,了解更多精彩—

B站

视频号